Many industries’ processes require the handling of bulk materials having different characteristics and able to satisfy multiple needs and customer requirements in terms of capacity, temperature, material size and process performances. Besides, some applications require also the compliance with special regulation such as PED or ATEX.

By using Caltech technologies, equipment and solutions, we supply complete handling systems, including the electrical & control package, able to comply with these requirements.

Each equipment is designed, case by case, according to the customer and process needs in order to optimize the performance of the complete system and minimize the maintenance costs.

Pneumatic Handling

We offer different pneumatic system solutions with both lean and dense phase technology. by using Clyde Pneumatic Conveying’s expertise and technology. The right solution is selected considering the material characteristics, the conveying distance, the capacity and the process where the system is installed.

The lean phase generally can cover distance up to 200 m with a low material capacity and it is indicated for not abrasive materials. In case of long distance and / or high material capacity, the dense phase technology is suggested in order to:

- minimize the energy consumption

- minimize the maintenance costs and wear problems

- reduce the CAPEX

Fuel Feeding

The fuel feeding system can be used with different materials such as biomass in general or RDF. It is mainly equipped with a metering hopper and a multi-screw conveyor that feeds the boiler directly. According to the application and customer requirements, the system can be completed with special lining to reduce the wear and guarantee the uniform material flow.

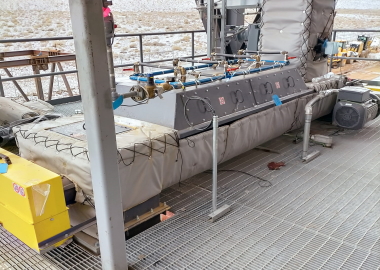

Material Cooling System

Some processes require the material cooling in order to meet the process requirements or to allow the material handling in a safe way. In these cases, we can supply a Water-Cooled Screw Conveyor or an Air-Cooled Conveyor. The choice depends on the different parameters like layout constrains, material capacity and site conditions. Caltech Cooling solutions can manage temperatures up to 1.000°C and capacity up to 20 tph.

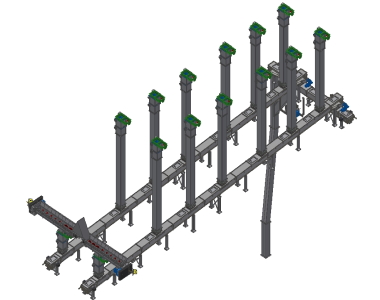

Extraction & Dosing

The extraction and dosing systems are generally required for bulk materials received by trucks that discharge into a hopper or in case of extraction from a storage silo. There are different solutions for the extraction phase and Multi-screw Conveyors, Belt Conveyors, Apron or Drag chain Conveyors can be used. The best solution is selected in order to guarantee the free-flow material extraction, without bridging or rathole in the material. For the solution selection it is very important to consider the abrasiveness and stickiness of the material to be extracted in order to avoid lack of it during the normal operation.

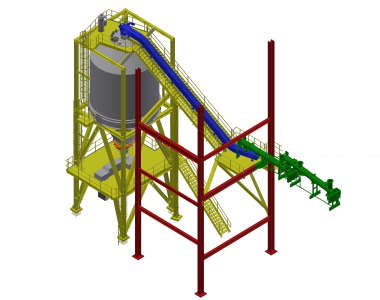

Loading & Unloading

We have a lot of experience and references with Silo, Wearhouse and Hopper Loading systems using our different technologies selected in accordance with materials to be conveyed. The unloading systems include generally extraction and dosing devices that can be huge in case of high material capacity or very compact in case of reagents dosing systems like active carbon, bicarbonate, lime and so on.

The unloading systems can be wet or dry and integrated with different equipment. The wet solution includes generally a dosing feeder and an humidifier with a water control system. In case of dry unloading, the system is much easier and includes a feeder with a discharge telescopic unloader.

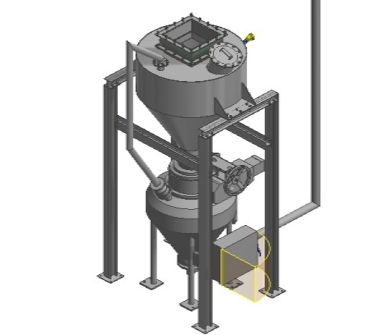

Skids

Some industries require movable or fix Stand Alone Skid Systems for different purpose (dosing, pneumatic feeding and so on) to be used generally for emergency or for some not continuous processes. The skid’s design is different case by case and is influenced in particular by the material characteristic to be conveyed in terms of Ex classification, capacity and site conditions. The skid needs only the power supply and generally is equipped with all necessary accessories like filtration, fluidization, air distribution, cabling and control panel.

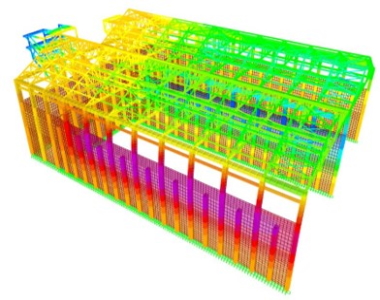

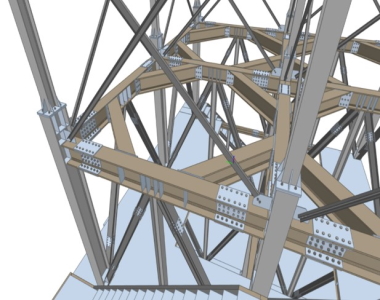

Multidisciplinary Design

Caltech team can provide engineering service to cover the different disciplines within a project and in particular:

- Mechanical Engineering

- Process Engineering

- Structural Engineering

- Civil Engineering

We start the design of the project since from the FEED stage developing different solutions for our customers in order to better control and evaluate the costs involved in the project.